Strobels Coatings delivers premium coatings and paint application services with a focus on quality, efficiency, and customization. With over 70 years of expertise in the industry, we specialize in advanced techniques and materials to meet the stringent requirements of diverse industries.

Now with two locations on the east coast, we can facilitate the process and logistics for any paint and coating production products throughout the mid-Atlantic region.

Hornell, NY Facility

Our 45,000 sq. ft. cutting-edge facility is designed to handle high-volume and complex projects, equipped with advanced systems to ensure precision and efficiency:

- Surface Preparation: Manual sanding, grinding, abrading, and sandblasting performed in dedicated a 2,500 sq. ft. contamination-free space for optimal preparation for adhesion.

- Sandblasting: Two dedicated 25’ x 25’ sandblast buildings

- Spray Booths: 5 Booths configured for various industrial project

- Two 36′ x 14′ x 14′

- Two 28′ x 14′ x 14′

- One 60′ x 18′ x 14′

- Drying Room: A dedicated 3,000 sq. ft. space for optimal curing and finishing.

- Robotic Buffing: Tailored buffing for client-specific requirements

Linwood, NC Facility

Our 65,000 sq. ft. facility is equipped with state-of-the-art systems to handle high-volume and complex projects efficiently:

- Surface Preparation: Manual sanding, grinding, abrading, and sandblasting performed in a dedicated 1,100 sq. ft. sandblast room.

- Spray Booths:

- Two 36’ x 14’ x 12’ booths with humidity control for precise applications.

- 60’ booth for large-scale projects.

Materials We Apply

- Epoxy : Durable and chemical-resistant coatings ideal for industrial environments.

- Urethane : Weather-resistant coatings perfect for outdoor and UV-exposed applications.

- Alkyd : Cost-effective solutions for metal, wood, and general-purpose applications.

- Clear Coats: Protective top layers that enhance gloss and provide scratch resistance.

- Base Coats: Foundational layers that deliver color and visual appeal for painted surfaces.

- Polyurea: Flexible and highly durable coatings ideal for abrasion resistance and long-term protection.

Substrate & Quality Expertise

- Stainless steel, aluminum, galvanized steel, and exotic metals.

- Fiberglass, plastics, and melamine.

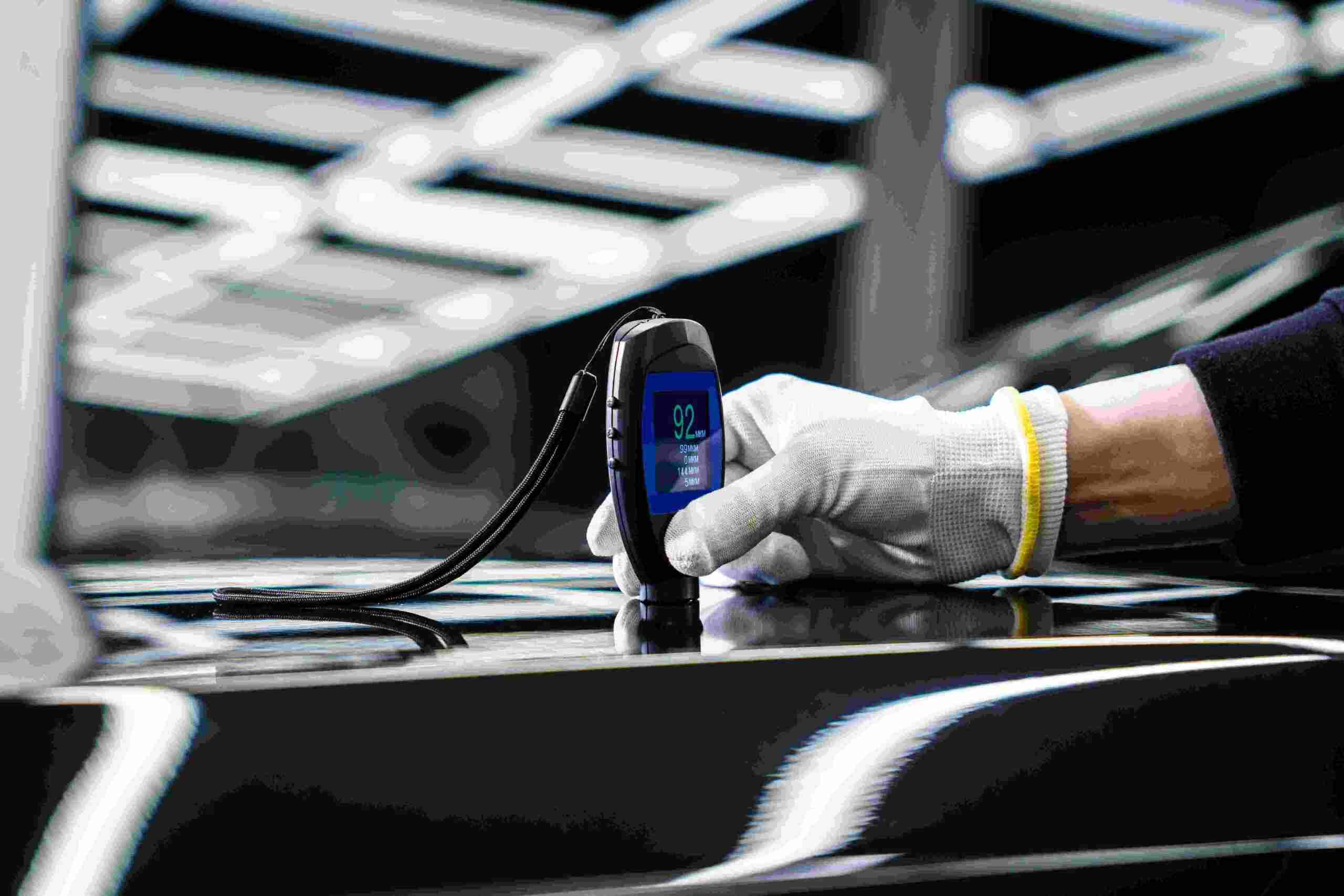

All necessary quality tests are done prior to packaging and shipping your parts. Our team will perform any of the tests below to your specifications:

- Delta E

- Nace II Certified

- Mil Readings

- Gloss Reading

- Dry Film Thickness (DFT) Mil Readings

- ASTM D3359 Adhesion Tests (Both X Test and Cross Hatch)

- Pencil Hardness Test